Toilet Cubicles can be constructed in a variety of materials depending on use case and budget. Cubicles in wet or humid environments require a material capable of withstanding water damage and washrooms with a high number of visitors benefit from more hard wearing materials to resist damage or vandalism.

Typically cubicles require two choices when it comes to materials, The boards that make up the panels & doors and the fittings such as locks and hinges.

This page will descibe what materials are commonly used and should help shed light on the meanings of some of the terms used to describe these panels.

Toilet Cubicle Panels

Cubicle Panels are often made from three types of materials which vary in toughness, water resistance and price.

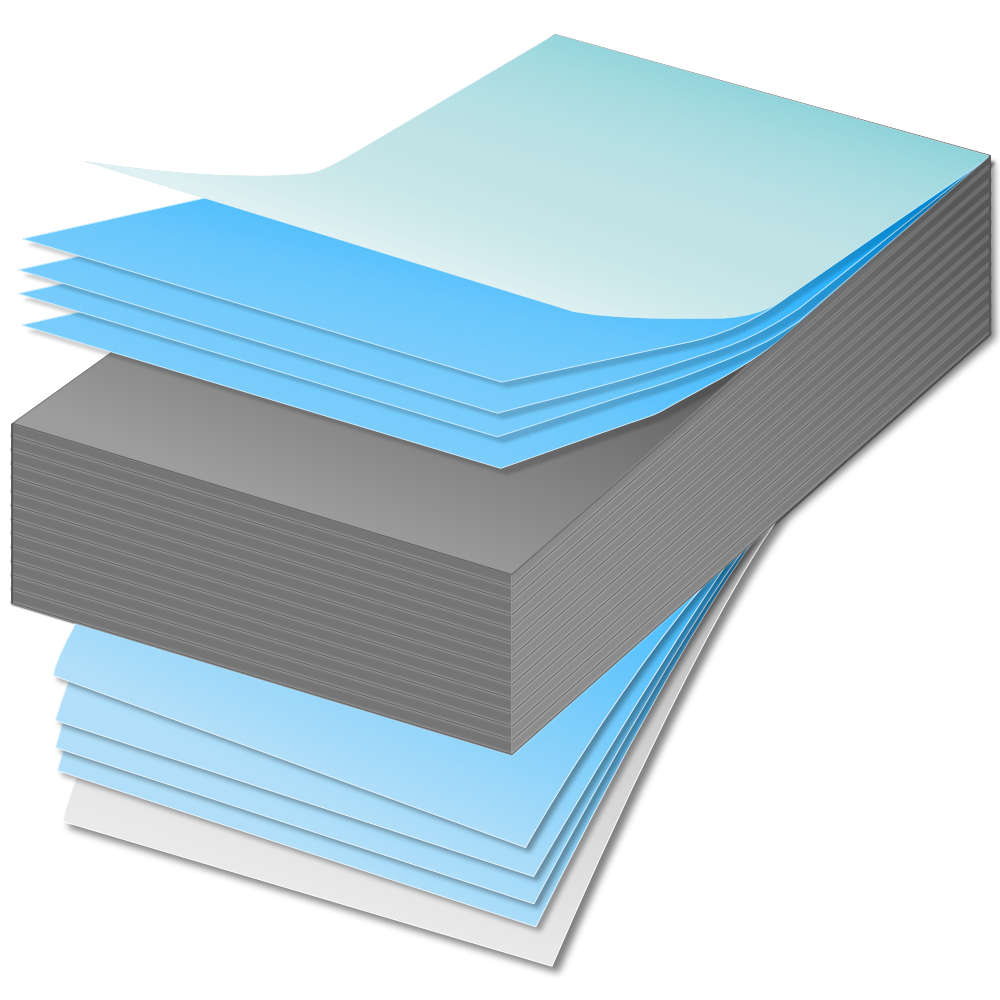

Solid Grade Laminate

Solid Grade Laminate, or SGL is both hard wearing and extremely water resistant while also offering antibacterial properties and being easy to wipe clean, making it a popular choice in Hospitals.

The panels are constructed from multiple layers of high quality, dyed kraft paper impregnated with thermosetting phenolic resins, giving the panel a characteristic black core appearance. The outer sides are are further layered wih a decorative paper and melamine resin allowing for a variety of colours and textures.

All of these layers together undergo the same heating and high pressure compression as HPL, to form a single high strength, tough and totally waterproof panel. The panel edges are machined to a smooth round profile, forming a complete self supporting panel with outstanding durability.

We reccomend SGL for use in:

- Areas with very high traffic

- Swimming pools and wet applications

- Shower cubicles or spas

- Locker and changing rooms

- Laboratory and healthcare

- Areas subject to wide temperature variations

- Area’s expposed to the elements, such as camp sites

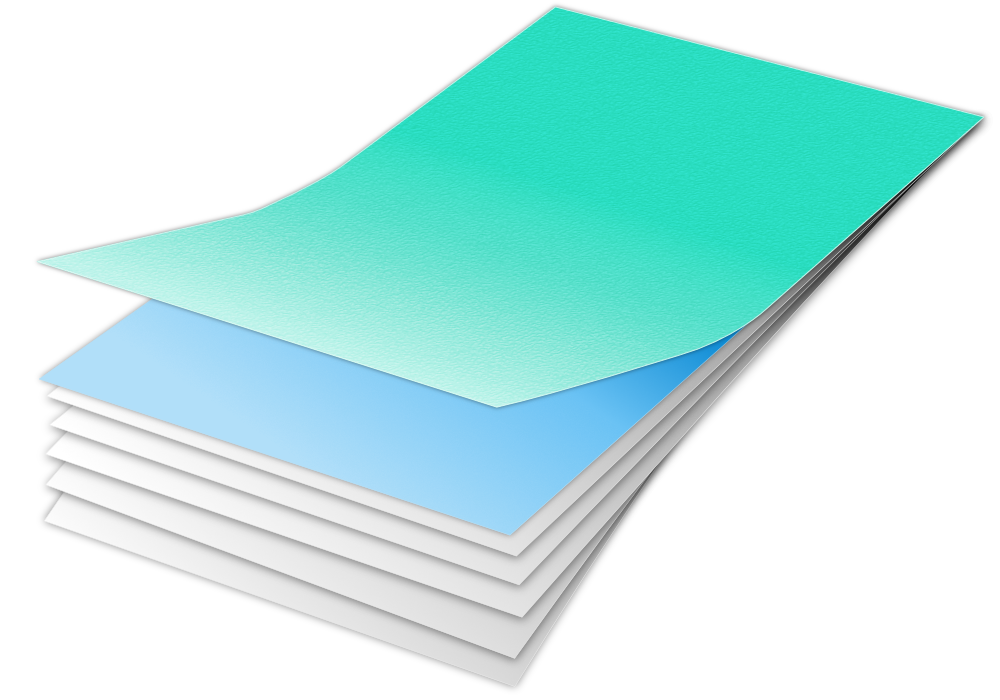

High Pressure Laminate

High Pressure Laminate, or SGL is a tough and durable laminate material that is ideally suited to heavy duty applications. It is a versatile material that has both High impact and scratch resistance while being water resistant and easy to clean.

A sheet is bonded to both sides of a suitable substrate, such as moisture resistant high density chipboard. For more demanding applications moisture resistant MDF or plywood may be used. The panel is then machined square and the edge lipped with durable, high impact PVC. Alternatively, panels can be post-formed, creating a softly curved edge detail.

We Reccomend HPL for use in:

- High traffic, Dry Area washroom cubicles

- Vanity Units

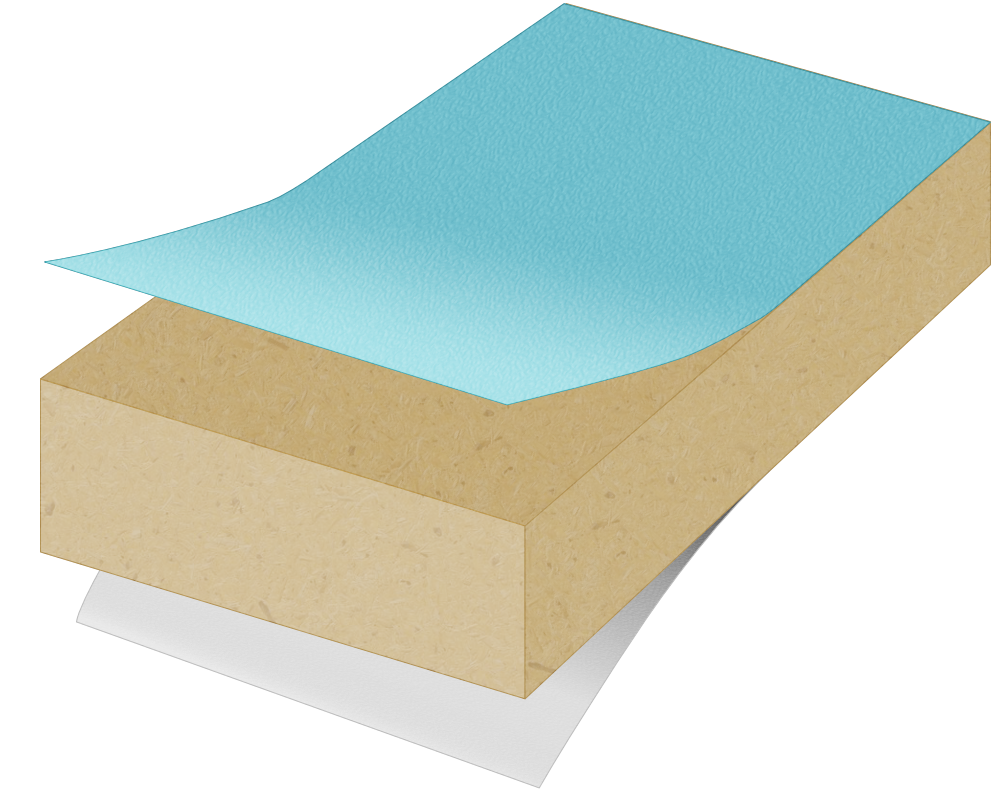

Melamine Faced Chipboard

Melamine Faced Chipboard, or MFC offers an economic, cost-conscious option for day-to-day applications. MFC is a best suited for toilet cubicles with lower traffic where abuse is unlikely.

MFC is manufactured with melamine impregnated decorative paper which is bonded under high pressure and temperature to both sides of a substrate – such as moisture resistant high density chipboard. All visible edges are lipped with durable, high impact PVC.

Toilet Cubicle Fittings

The Cubicle fittings material options are mostly for aesthetic reasons although some materials do fair better in particular environments.

Stainless Steel

Stainless Steel fittings are reliable and durable especially in wet or high humidity environments.

Satin Anodized Aluminium

Fittings made from Satin Anodized Aluminium, or SAA fittings are a common lower cost option. While not as hard wearing as Stainless Steel they are suitible for any cubicles that aren’t expected to encounter abuse, high traffic use or wet environments.

Plastic

Shower Cubicles often use plastic fittings instead of metal because of their tolerance to temperature changes, heavy water exposure and their anti-slip grips.